That amount is added to the cost of the job, and the amount in the manufacturing overhead account is reduced by the same amount. At the end of the year, the amount of overhead estimated and applied should be close, although it is rare for the applied amount to exactly equal the actual overhead. For example, Figure 4.18 shows the monthly costs, the annual actual cost, and the estimated overhead for Dinosaur Vinyl for the year. Cost accountants want to be able to estimate and allocate overhead costs like rent, utilities, and property taxes to the production processes that use these expenses indirectly. Since they can’t just arbitrarily calculate these costs, they must use a rate.

Basis

Knowing the overhead cost per unit allows the business to set competitive pricing while still covering their indirect expenses. The key is choosing an appropriate cost driver – like machine hours in manufacturing or headcount in sales – to distribute overhead expenses. Rather than lump overhead costs into one expense account, businesses should allocate fixed and variable overhead to departments. This option is best if you’re just starting out and don’t have any historical data to work with. Companies need to make certain the Accounting Security sales price is higher than the prime costs and the overhead costs. In some industries, the company has no control over the costs it must pay, like tire disposal fees.

How to calculate the predetermined overhead rate

A predetermined overhead rate is calculated at the start of the accounting period by dividing the estimated manufacturing overhead by the estimated activity base. The predetermined overhead rate is then applied to production to facilitate determining a standard cost for a product. The predetermined overhead rate allocates estimated total overhead for an accounting period across expected activity or production volume. It is calculated before the period begins and is used to assign overhead costs to production using an allocation rate per unit of activity, such as direct labor hours. Added to these issues is the nature of establishing an overhead rate, which is often completed months before being applied to specific jobs. Establishing the overhead allocation rate first requires management to identify which expenses they consider manufacturing overhead and then to estimate the manufacturing overhead for the next year.

- However, there is a strong need to constantly update the production level depending on the seasonal fluctuations and the factor affecting the demand of the product.

- Calculating a predetermined overhead rate is one of the first tasks management will take on because it provides a formula to estimate the production costs of a product in advance.

- Examples of manufacturing overhead costs include indirect materials, indirect labor, manufacturing utilities, and manufacturing equipment depreciation.

- Additionally, you should recalculate your predetermined overhead rate any time there is a significant change in your business, such as the addition of new equipment or a change in your product line.

- But if actual overhead were $1,400,000, the underapplied amount ($100,000) would require adjustment.

- For example, if we choose the labor hours to be the basis then we will multiply the rate by the direct labor hours in each task during the manufacturing process.

- Commonly, the manufacturing overhead cost for machine hours can be ascertained from the predetermined overhead rate in the manufacturing industry.

Calculations

- They enable businesses to compare actual overhead costs with the estimated rates, identify variances, and take corrective actions if necessary.

- So, a more precise practice of overhead absorption has been developed that requires different and relevant bases of apportionment.

- However, the problem with absorption/traditional costing is that we have to ignore individual absorption bases and absorb all overheads using a single level of activity.

- The predetermined overhead rate takes these variations into consideration and offers a more dependable estimated overhead total.

- Using a predetermined overhead rate is advantageous to company planners because it helps them form strategies for the future.

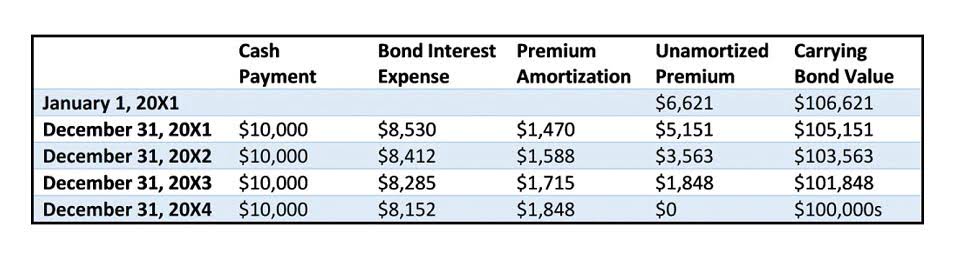

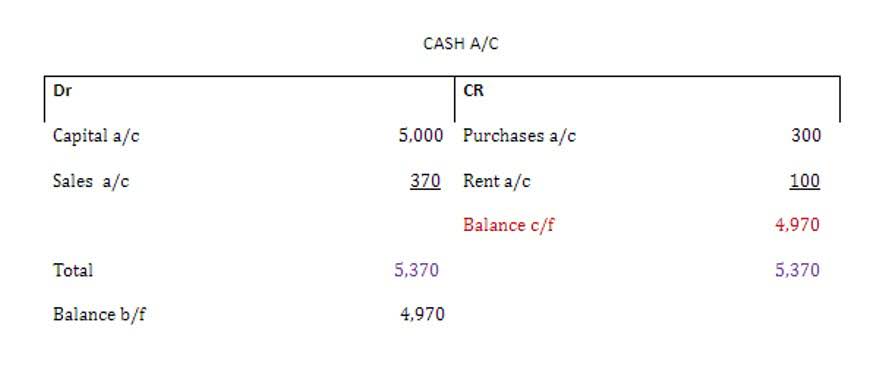

At the end of the accounting period the applied overhead is compared to the actual overhead and any difference is posted to the cost of assets = liabilities + equity goods sold or, if significant, to work in process. We’ll outline the basic formulas used to calculate different types of overhead rates and provide overhead cost examples. This predetermined overhead rate can be used to help the marketing agency price its services. These costs cannot be easily traced back to specific products or services and are typically fixed in nature. If the business used the traditional costing/absorption costing system, the total overheads amounting to $26,000 will be absorbed using labor hours. Predetermined overhead rates are applied in various financial and operational areas.

- That is, if the predetermined overhead rate turns out to be inaccurate and the sales and production decisions are made based on this rate, then the decisions will be faulty.

- The actual cost of a particular project, however, should be evaluated independently of the season in which the project is completed.

- The estimated manufacturing overhead cost applied to the job during the accounting period will be 1,494.

- In general, management teams will divide expenses between these two categories because they provide broader insight into an accurate product cost and the manufacturing of a product.

- Further, it is stated that the reason for the same is that overhead is based on estimations and not the actuals.

When calculated correctly, the debit or credit will be minor, and it makes the process for accounting simple. Yes, it’s a good idea to have predetermined overhead rates for each area of your business. Now, let’s look at some hypothetical business models to see actual use-cases for predetermined overhead rates.

Real-World Application: A Manufacturing Case Study

As a result, two identical jobs, one completed in the winter and one completed in the spring, would be assigned different manufacturing overhead costs. To avoid such fluctuations, actual overhead rates could be computed on an annual or less-frequent predetermined overhead rate basis. However, if the overhead rate is computed annually based on the actual costs and activity for the year, the manufacturing overhead assigned to any particular job would not be known until the end of the year. For example, the cost of Job 2B47 at Yost Precision Machining would not be known until the end of the year, even though the job will be completed and shipped to the customer in March. For these reasons, most companies use predetermined overhead rates rather than actual overhead rates in their cost accounting systems.

4: Compute a Predetermined Overhead Rate and Apply Overhead to Production

Knowing the total and component costs of the product is necessary for price setting and for measuring the efficiency and effectiveness of the organization. Remember that product costs consist of direct materials, direct labor, and manufacturing overhead. A company’s manufacturing overhead costs are all costs other than direct material, direct labor, or selling and administrative costs. Once a company has determined the overhead, it must establish how to allocate the cost. This allocation can come in the form of the traditional overhead allocation method or activity-based costing..